We have migrated to a new, more secure platform. If this is your first visit since our update, you must create a new account during checkout. Call 1-800-828-1496 or 905-683-9223 for assistance.

Categories

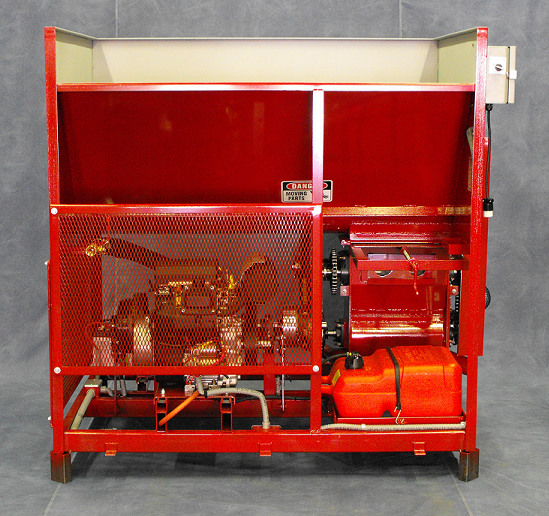

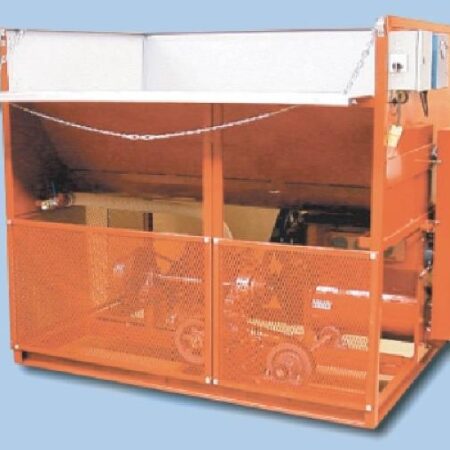

HS 5000 Gas

AIRLOCK EXHAUSTER: This bleed off mechanism results in impoved coverage and greatly reduces the dust in the attic.

OUTPUT: Cellulose 117bags/hr (3,500lbs – 1,590 kg), Fiberglass 50 bags/hr (2,160 lbs – 987 kg), Rockwool 45 bags/hr (1,620 lbs – 736 kg)

POWER: 22HP cylinder Honda gasoline engine complete with electric start, 20 amp alternator, spin-on oil filter, pressurized lubrication, muffler exhaust system, stainless steel flexible tubing, 6 gallon tank.

DOUBLE CLUTCHES: Electro-magnetic double clutches allow air and material flow to be controlled individually by remote control. Expected life 10 to 15 years.

SAFETY CONTROL: Safety clutch will slip if any foreign material jams the machine.

POWER CONTROLS: Motor mounted ignition switch, choke, throttle control and digital tachometer, hourmeter.

REMOTE CONTROL: Box mounted on side of machine. Totally separate from ignition system. Relays are plug in type. 150′ remote cord supplied.

AIR CONTROL: Bleed off valves can be operated independently. One way air valve prevents insulation from backing up into blower.

MATERIAL CONTROL: Slide gate.

HOPPER: 30 cubic foot capacity, made with heavy gauge metal with heavy-duty reinforced feeder paddles for uniform material feed.

SHREDDER: Double shredder with self-cleaning tines. Hinged doors on each side for easy access. Front door has plexiglass material feed monitoring window.

AIRLOCK CHAMBER: Rotary type, plate steel construction (wear resistant), 16″ long with 12″ diameter with 4″ outlet. (Recommend 150′ of 3.5″ hose)

BLOWER: Positive displacement 3L rotary lobe blower. 6 psi, 307 CFM

DIMENSIONS: 44″ wide, 66″ long, 60″ high. Shipping weight: 1,320 lbs

INSTALLATION: When installed correctly, only outside air is used for: Cooling of Gas Engine, Engine Carburetor, Blower Intake