The Four Stages Of Insulation Blowing Machine Maintenance

Whether you use a gas- or diesel-powered insulation blowing machine, maximizing output is critical, and that can only happen if you maintain it properly.

After all, it is not just a piece of equipment; it is your business’s revenue engine. You need to treat it with the care it deserves so it can continue to deliver consistent performance with fewer breakdowns. Neglecting basic upkeep can have the opposite effect, leading to downtime-related expenses, frustrated teams, and a damaged market reputation.

However, before you start the maintenance process, did you know there are four stages to it? In this blog, Heat Seal Equipment Ltd., the topmost provider of insulation equipment in Ontario, will shed light on all 4 stages so you can level up your machine maintenance game.

What Are The Four Stages Of Maintaining An Insulation Blowing Machine?

Even though it covers four separate stages, maintaining an insulation blowing machine is easy work, provided you follow the method we have given below. Let’s begin.

Stage #1: Conduct daily checks

Before you fire up your insulation blower each morning, make sure you conduct a couple of mandatory pre-operation checks that will not take more than 5-10 minutes of your time each day. These include:

- Visually inspect hoses and connections

Check connections to ensure they are secure and devoid of any sort of damage. As for hoses, make sure they are free of cracks, kinks, and excessive wear, as the condition of the hose you use has a direct impact on air quality.

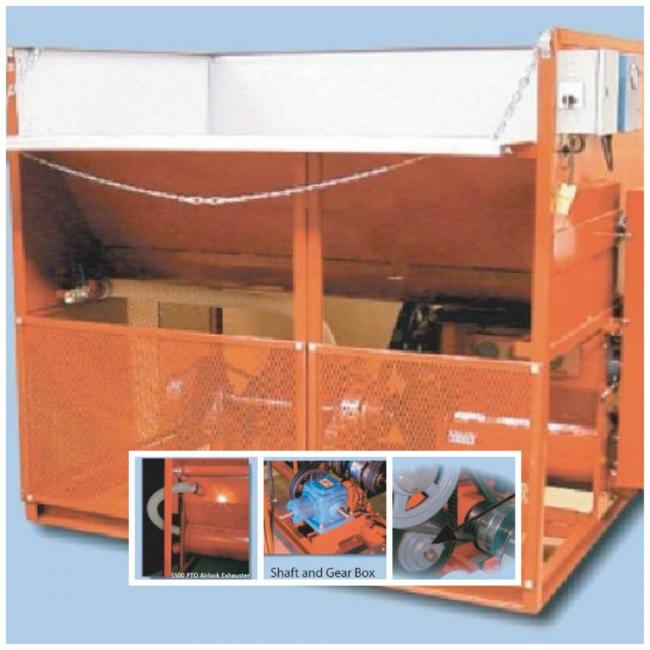

- Check the hopper and shredder

Make sure both are free of debris. Whether large or small, the accumulation of any kind can dramatically reduce shredding performance.

- Engine and fuel levels

Verify the levels of oil, fuel, and coolant of your machine. Make sure you also check the condition of its belt and engine. If your equipment’s fluid levels are low, top them up before starting the machine, or it can overheat.

Stage #2: Carry out weekly cleaning and basic servicing

At the end of every week, subject your insulation blowing machine to the following cleanup routine:

- Blower and airlock cleaning

Residual dust is highly likely to build up inside the airlock mechanism and around the blades of your machine. You can clean it out with the help of compressed air. Just be sure to wear appropriate PPE before you start cleaning.

- Inspect seals and gaskets

Air leaks can hamper consistent blowing performance. To prevent them, check all seals for cracks and compression. Replace damaged or loose ones immediately.

- Grease fittings and moving parts

While daily lubrication is not required, weakly greasing is necessary to prevent and prolong the life of moving parts.

Stage #3: Perform monthly mechanical checks

Monthly checks are all about verifying the condition of your insulation blowing machine on a deeper level. However, they are still quite quick and easy to perform.

- Check engine systems

Replace the oil if required. Apart from that, make sure air filters and spark plugs are in good condition.

- Belts, pulleys, and tensioners

Signs such as frayed or misaligned belts, off-angle pulleys, and faulty tensioners could be the cause behind reduced power transfer and increased wear.

- Check the blower system

Look for dents, foreign objects, or imbalances when inspecting the fan housing and impeller, as these might be responsible for uneven airflow.

Stage #4: Organize annual maintenance checks

Once every year, before the busiest season begins, schedule a full servicing of your insulation blowing machine that includes:

- Filter and parts replacement

Replacing filters annually is a must as it can boost efficiency and reduce machine strain. The same holds true for swapping worn-down parts with new ones.

- Electrical systems and controls evaluation

From wiring to switches, gauges, and connections – every component that is performing sub-optimally should be either repaired or replaced.

- Calibrate pressure and flow controls

If your insulation blowing machine features components such as adjustable gates, bleeders or remote controls, make sure you calibrate them annually to maintain consistent performance.

- Professional servicing

Once every year, get a qualified technician to evaluate your machine – particularly its belts, bearings, engine, and safety system so appropriate measures can be taken to address any issues found.

Conclusion

Insulation blowing machines are the most valuable asset for insulation contractors. You can protect your investment and ensure it serves you in the long run by following our four-stage maintenance guide. It is a simple and effective way to reduce costly downtime and keep your crew productive.

Heat Seal Equipment Ltd. provides top-notch insulation blowing machines that are easy to maintain and repair in Ajax, Ontario. Contact us to make our powerful performers a part of your insulation blowing setup.

FAQs

How often should an insulation blower’s air filters be changed?

Cleaning air filters out every week is recommended, and so is replacing them once every season.

Which daily maintenance task is the most critical when it comes to insulation blowing machines?

Carefully inspecting hoses and connections for wear and tear is critical, as these issues are easy to miss.

Is it necessary to flush the insulation blowing machine after every job?

Yes. Flushing your machine can help you remove accumulated debris, thus preventing issues such as clogs and excessive buildup.