5 Common Issues with Air Compressors in Duct Cleaning and Their Fixes

A must-have when it comes to duct cleaning, air compressors provide the power and airflow necessary to clean HVAC systems of pesky dust, debris and allergens. Despite the crucial role they play in HVAC clean-up, duct cleaning air compressors, like any other machinery, are not immune to the occasional hiccup, requiring immediate action to counter the problem.

Problems in the normal functioning of air compressors can lead to issues such as reduced efficiency, disruption in operation as well as costly downtime. Problems that can be avoided if you know how to avoid them.

In this blog, Heat Seal Equipment Ltd. will walk you through the common issues with air compressors during duct cleaning along with their solutions.

1. Inadequate Air Pressure

A drop in air pressure is a common issue that can affect most air compressors. This, in turn, can reduce its efficiency in cleaning ducts. The most common causes behind this problem include blocked filters, leaks in the air hose, or faulty pressure regulators.

The key to fixing this is to, first and foremost, check the air hoses for leaks. Make sure you regularly and thoroughly inspect them for signs of wear as well as loose fittings and connections. You should also clean or replace clogged filters as they can reduce airflow too.

Finally, you should set the pressure regulator correctly and test it to see if it’s functioning properly. If it does not, chances are it’s faulty and needs a replacement.

2. Overheating Machinery

Cleaning ducts can take a lot of time. Using your air compressor continuously may cause it to overheat, leading to issues such as reduced efficiency as well as damage to internal components. Other reasons why your air compressor might overheat include low levels of lubricant, poor ventilation and a clogged cooling system.

The solution lies in using your air compressor in a well-ventilated area so it doesn’t heat as easily with prolonged use. Barring that, you must also clean your compressor’s cooling system so optimal airflow can be maintained. Lastly, topping up lost lubricant and using the correct type of oil can also mitigate the problem of overheating.

3. Unusual Noisiness

If your duct cleaning air compressor gets excessively loud during operation, it could indicate an underlying issue. For example, improper alignment of internal components or worn bearings can lead to loud noises.

Inspecting your air compressor thoroughly can point out the culprit behind the racket. If you find loose bolts, fittings or screws, tighten them immediately. If that doesn’t resolve the issue, try replacing worn-out bearings or re-aligning wonky parts as per the manufacturer’s guidelines. Taking these steps can prevent the issue of noise and vibration from arising again.

4. Motor Overload

Though motor overload is acceptable once in a while, if it happens frequently, it might be a cause for concern. Machine overuse, electrical issues and clogged air intake might cause this duct cleaning tool to trip or shut down frequently.

An easy fix is to repair loose or faulty electrical connections. However, if that’s not the cause, you might need to check and clean the compressor’s air intake to see if it is clogged. Furthermore, you should let your compressor rest after extended use to prevent putting strain on its motor.

5. Failure To Function

An air compressor that refuses to start may be facing a wide range of issues such as a tripped circuit breaker, faulty starter or depleted power supply. Fortunately, each of these has an easy fix.

The first thing you should do is check if the compressor is plugged in correctly and is receiving power. If not, check the access point with another device to see if it’s functioning properly. Next, check the starter. If it’s faulty, it might need replacement. You can also reset your circuit breaker in case it has tripped.

Conclusion

Duct cleaning tools such as air compressors require proper care and maintenance to perform efficiently. Troubleshooting common issues can help you avoid frustration, especially on busy work days. Investing in a high-quality air compressor can make a significant difference.

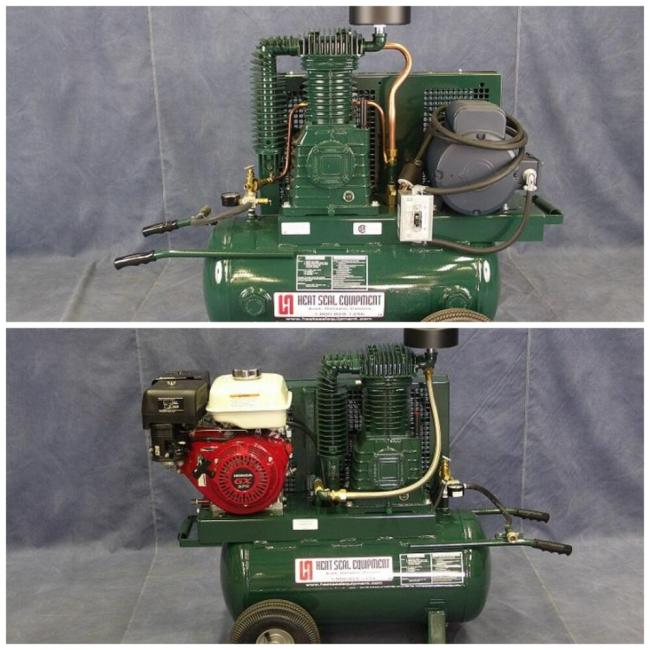

At Heat Seal Equipment Ltd., we’ve got both portable electric as well as gas air compressors for you to choose from. Contact us today to get access to high-quality compressors that are built to last.